Biodegradable Polymers—a Review on Properties, Processing, and Degradation Mechanism

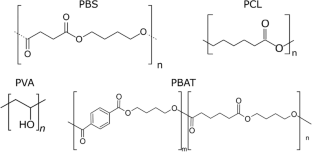

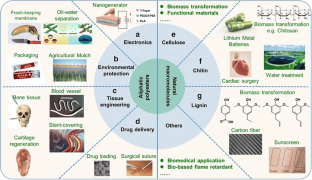

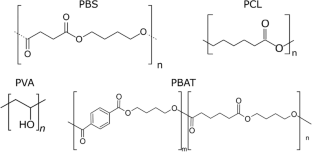

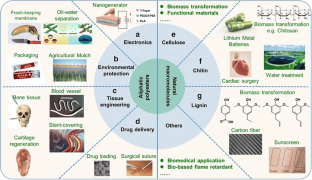

Pollutants in the environment are growing as a result of the use of plastic. Our environment and food chain contain plastic particles and other pollutants made of plastic, threatening human health. From this point of view, biodegradable plastic material focuses on building a more sustainable, greener world with a lower impact on the environment. This evaluation should be kept in view of the objectives and priorities for producing a wide variety of biodegradable plastics throughout their entire life cycle. The properties of biodegradable plastics are similar to traditional plastics. Additionally, the greatest benefits of biodegradable polymeric materials are the preservation of fossil fuel resources and the reduction of environmental pollution in the environment of sustainable development. This review summarizes the main synthesis methods and the most common type of biodegradable polymers. Lastly, the biodegradation mechanism of biodegradable polymers is also discussed.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save

Springer+ Basic

€32.70 /Month

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Buy Now

Price includes VAT (France)

Instant access to the full article PDF.

Rent this article via DeepDyve

Similar content being viewed by others

Biodegradable Polymers

Chapter © 2023

Biodegradable Polymers

Chapter © 2022

Synthetic-Origin Biodegradable Polymers

Chapter © 2023

Explore related subjects

Data Availability

References

- Ricciardi M, Pironti C, Motta O, Miele Y, Proto A, Montano L (2021) Microplastics in the aquatic environment: occurrence, persistence, analysis, and human exposure. Water 13(7):973 CASGoogle Scholar

- Lebreton L, Andrady A (2019) Future scenarios of global plastic waste generation and disposal. Palgrave Commun 5(1):1–11 Google Scholar

- Yin G, Yang X (2020) Biodegradable polymers: a cure for the planet, but a long way to go. J Polym Res 27(2):38 CASGoogle Scholar

- Moshood T, Nawanir G, Mahmud F, Mohamad F, Ahmad M, AbdulGhani A (2022) Sustainability of biodegradable plastics: new problem or solution to solve the global plastic pollution? Curr Res Green Sustain Chem 5:100273 CASGoogle Scholar

- Steven S, Mardiyati Y, Mar’atusShoimah S, Rizkiansyah R, PujiSantosa S, Suratman R (2021) Preparation and characterization of nanocrystalline cellulose from Cladophora sp. Algae. Int J Adv Sci Eng Inf Technol 11(3):1035 Google Scholar

- Tábi T (2022) Biodegradable bio-based plastics: compostable or recyclable? Express Polym Lett 16(2):115–115 Google Scholar

- Iwata T (2015) Biodegradable and bio-based polymers: future prospects of eco-friendly plastics. Angew Chem Int Ed 54(11):3210–3215 CASGoogle Scholar

- Di Bartolo A, Infurna G, Dintcheva N (2021) A review of bioplastics and their adoption in the circular economy. Polymers 13(8):1229 PubMedPubMed CentralGoogle Scholar

- Wang J, Tan Z, Peng J, Qiu Q, Li M (2016) The behaviors of microplastics in the marine environment. Mar Environ Res 113:7–17 CASPubMedGoogle Scholar

- Ghimire S, Flury M, Scheenstra E, Miles C (2020) Sampling and degradation of biodegradable plastic and paper mulches in field after tillage incorporation. Sci Total Environ 703:135577 ADSCASPubMedGoogle Scholar

- Nanda S, Patra B, Patel R, Bakos J, Dalai A (2021) Innovations in applications and prospects of bioplastics and biopolymers: a review. Environ Chem Lett 20(1):379–395 PubMedPubMed CentralGoogle Scholar

- Gunawardene O, Gunathilake C, Amaraweera S, Fernando N, Wanninayaka D, Manamperi A, Kulatunga A, Rajapaksha S, Dassanayake R, Fernando C, Manipura A (2021) Compatibilization of starch/synthetic biodegradable polymer blends for packaging applications: a review. J Compos Sci 5(11):300 CASGoogle Scholar

- Yang J, Ching Y, Chuah C (2019) Applications of lignocellulosic fibers and lignin in bioplastics: a review. Polymers 11(5):751 CASPubMedPubMed CentralGoogle Scholar

- Vasile C, Cazacu G (2013) Biocomposites and nanocomposites containing lignin. Biopolymer Nanocomposites, pp. 565–598.

- Luzi F et al (2019) Bio- and fossil-based polymeric blends and nanocomposites for packaging: structure–property relationship. Materials 12(3):471 ADSCASPubMedPubMed CentralGoogle Scholar

- Murariu M et al (2022) Recent advances in production of ecofriendly polylactide (pla)–calcium sulfate (anhydrite II) composites: from the evidence of filler stability to the effects of PLA matrix and filling on key properties. Polymers 14(12):2360 CASPubMedPubMed CentralGoogle Scholar

- Dufresne A, Thomas S, Pothan LA (2013) Bionanocomposites: state of the art, challenges, and opportunities. Biopolymer Nanocomposites, pp. 1–10.

- Dintcheva NT et al (2020) Natural compounds as sustainable additives for biopolymers. Polymers 12(4):732 CASPubMedPubMed CentralGoogle Scholar

- Post W et al (2021) Effect of mineral fillers on the mechanical properties of commercially available biodegradable polymers. Polymers 13(3):394 CASPubMedPubMed CentralGoogle Scholar

- Morreale M et al (2015) Mechanical, thermomechanical and reprocessing behavior of green composites from biodegradable polymer and wood flour. Materials 8(11):7536–7548 ADSCASPubMedPubMed CentralGoogle Scholar

- Varyan I et al (2022) Biodegradability of polyolefin-based compositions: effect of natural rubber. Polymers 14(3):530 CASPubMedPubMed CentralGoogle Scholar

- Zhang Y, Wei J, Zhu Y, George-Ufot G (2020) Untangling the relationship between corporate environmental performance and corporate financial performance: the double-edged moderating effects of environmental uncertainty. J Clean Prod 263:121584 Google Scholar

- Moshood T, Nawanir G, Mahmud F, Mohamad F, Ahmad M, AbdulGhani A (2022) Biodegradable plastic applications towards sustainability: a recent innovations in the green product. Clean Eng Technol 6:100404 Google Scholar

- ASTM D6400–12 (2012) Standard specification for labeling of plastics designed to be aerobically composted in municipal and industrial facilities. ASTM Google Scholar

- Hubbe M, Lavoine N, Lucia L, Dou C (2020) Formulating bioplastic composites for biodegradability, recycling, and performance: a review. BioResources 16(1):2021–2083 Google Scholar

- Muthuraj R, Misra M, Mohanty A (2017) Biodegradable compatibilized polymer blends for packaging applications: a literature review. J Appl Polym Sci 135(24):45726 Google Scholar

- Scaffaro R et al (2021) Green composites based on PLA and agricultural or marine waste prepared by FDM. Polymers 13(9):1361 CASPubMedPubMed CentralGoogle Scholar

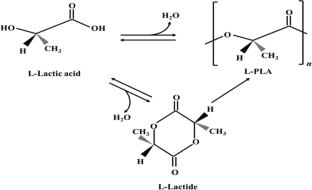

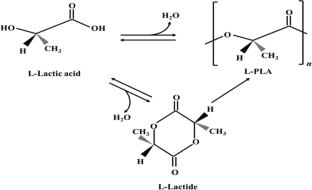

- Swetha TA et al (2023) A comprehensive review on polylactic acid (PLA) – synthesis, processing and application in food packaging. Int J Biol Macromol 234:123715 CASPubMedGoogle Scholar

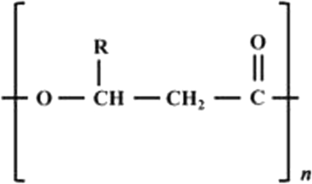

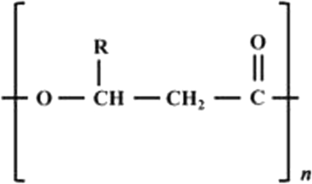

- Reddy V, Ramanaiah S, Reddy M, Chang Y (2022) Review of the developments of bacterial medium-chain-length polyhydroxyalkanoates (mcl-PHAs). Bioengineering 9(5):225 CASPubMedPubMed CentralGoogle Scholar

- Nagarajan V, Mohanty A, Misra M (2016) Perspective on polylactic acid (PLA) based sustainable materials for durable applications: focus on toughness and heat resistance. ACS Sustain Chem Eng 4(6):2899–2916 CASGoogle Scholar

- Elsawy M, Kim K, Park J, Deep A (2017) Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew Sustain Energy Rev 79:1346–1352 CASGoogle Scholar

- Atiwesh G, Mikhael A, Parrish C, Banoub J, Le T (2021) Environmental impact of bioplastic use: a review. Heliyon 7(9):e07918 CASPubMedPubMed CentralGoogle Scholar

- Chen X (2013) An optimized design of injection molding process parameters for supporting-foot plastic part based on CAE. Adv Mater Res 721:648–651 ADSGoogle Scholar

- Chan C, Vandi L, Pratt S, Halley P, Richardson D, Werker A, Laycock B (2020) Mechanical stability of polyhydroxyalkanoate (PHA)-based wood plastic composites (WPCs). J Polym Environ 28(5):1571–1577 CASGoogle Scholar

- Meereboer K, Misra M, Mohanty A (2020) Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem 22(17):5519–5558 CASGoogle Scholar

- Rivera-Briso A, Serrano-Aroca Á (2018) Poly (3-hydroxybutyrate-co-3- hydroxyvalerate): enhancement strategies for advanced applications. Polymers 10(7):732 PubMedPubMed CentralGoogle Scholar

- Naser A, Deiab I, Darras B (2021) Poly (lactic acid) (PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: a review. RSC Adv 11(28):17151–17196 ADSCASPubMedPubMed CentralGoogle Scholar

- Dalton B, Bhagabati P, De Micco J, Padamati R, O’Connor K (2022) A review on biological synthesis of the biodegradable polymers polyhydroxyalkanoates and the development of multiple applications. Catalysts 12(3):319 CASGoogle Scholar

- Choi S, Cho I, Lee Y, Kim Y, Kim K, Lee S (2020) Microbial polyhydroxyalkanoates and nonnatural polyesters. Adv Mater 32(35):1907138 CASGoogle Scholar

- Kumar V, Sehgal R, Gupta R (2021) Blends and composites of polyhydroxyalkanoates (PHAs) and their applications. Eur Polymer J 161:110824 CASGoogle Scholar

- Li Y, Yu H, Li W, Liu Y, Lu X (2021) Recyclable polyhydroxyalkanoates via a regioselective ring-opening polymerization of α, β-disubstituted β-lactone monomers. Macromolecules 54(10):4641–4648 ADSCASGoogle Scholar

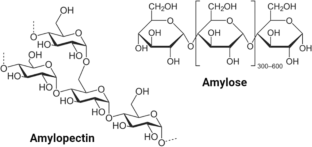

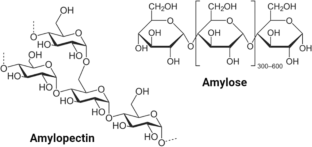

- Zarski A, Bajer K, Kapuśniak J (2021) Review of the most important methods of improving the processing properties of starch toward non-food applications. Polymers 13(5):832 CASPubMedPubMed CentralGoogle Scholar

- Mottiar Y, Altosaar I (2011) Iodine sequestration by amylose to combat iodine deficiency disorders. Trends Food Sci Technol 22(6):335–340 CASGoogle Scholar

- Cornejo-Ramírez Y, Martínez-Cruz O, Del Toro-Sánchez C, Wong-Corral F, Borboa- Flores J, Cinco-Moroyoqui F (2018) The structural characteristics of starches and their functional properties. CyTA - J Food 16(1):1003–1017 Google Scholar

- Biliaderis C (2010) ChemInform abstract: structures and phase transitions of starch polymers. ChemInform, 29(47), p.no-no.

- Helen Nwakego A-O et al (2022) Physicochemical, functional, pasting properties and Fourier transform infrared spectroscopy of native and modified Cardaba Banana (Musa Abb) starches. Food Chem Adv 1:100076 Google Scholar

- Liu C et al (2022) Influence of phosphorylation and acetylation on structural, physicochemical and functional properties of chestnut starch. Polymers 14(1):172 CASPubMedPubMed CentralGoogle Scholar

- Zia-ud-Din, Xiong H, Fei P (2017) Physical and chemical modification of starches: a review. Crit Rev Food Sci Nutr, 57(12), pp. 2691–2705

- Bhatt P et al (2022) Structural modifications and strategies for native starch for applications in advanced drug delivery. Biomed Res Int 2022:1–14 Google Scholar

- Bensaad DE et al (2022) Chemical modifications of starch; a prospective for sweet potato starch. Jordan J Agric Sci 18(4):293–308 Google Scholar

- Wang Z et al (2022) Cassava starch: chemical modification and its impact on functional properties and digestibility, a Review. Food Hydrocoll 129:107542 CASGoogle Scholar

- Trela VD, Ramallo AL, Albani OA (2020) Synthesis and characterization of acetylated cassava starch with different degrees of substitution. Braz Arch Biol Technol.

- Zhang C, Xu D, Zhu Z (2014) Octenylsuccinylation of cornstarch to improve its sizing properties for polyester/cotton blend spun yarns. Fibers Polym 15(11):2319–2328 CASGoogle Scholar

- Liu J, Yang R, Yang F (2015) Effect of the starch source on the performance of cationic starches having similar degree of substitution for papermaking using deinked pulp. BioResources 10(1):922–931 Google Scholar

- Chung H-J, Jeong H-Y, Lim S-T (2003) Effects of acid hydrolysis and defatting on crystallinity and pasting properties of freeze-thawed high amylose corn starch. Carbohyd Polym 54(4):449–455 CASGoogle Scholar

- Faridah DN, Rahayu WP, Apriyadi MS (2013) Modification of arrowroot starch through acid hydrolysis and autoclaving-cooling cycling treatment to produce resistant starch type 3. JTIP 23:61–69 Google Scholar

- Fonseca LM et al (2015) Oxidation of potato starch with different sodium hypochlorite concentrations and its effect on biodegradable films. LWT Food Sci Technol 60(2):714–720 CASGoogle Scholar

- Rahim A et al (2022) Effect of ph and acetic anhydride concentration on physicochemical characteristics of acetylated sago starch. IOP Conf Ser: Earth Environ Sci 1107(1):012124 MathSciNetGoogle Scholar

- Chen P, Yu L, Simon G, Liu X, Dean K, Chen L (2011) Internal structures and phase-transitions of starch granules during gelatinization. Carbohyd Polym 83(4):1975–1983 CASGoogle Scholar

- Jaysree R, Subhash Chandra K, Sankar T (2019) Biodegradability of synthetic plastics – a review. Int J ChemTech Res 12(6):125–133 CASGoogle Scholar

- Technische Textilien, 2021. Plastic waste and recycling — environmental impact, societal issues, prevention, and solutions. 64(2), pp.78–78.

- Bher A et al (2022) Biodegradation of biodegradable polymers in mesophilic aerobic environments. Int J Mol Sci 23(20):12165 CASPubMedPubMed CentralGoogle Scholar

- Quecholac-Piña X et al (2020) Degradation of plastics under anaerobic conditions: a short review. Polymers 12(1):109 PubMedPubMed CentralGoogle Scholar

- Takashima M, Yaguchi J (2020) High-solids thermophilic anaerobic digestion of sewage sludge: effect of ammonia concentration. J Mater Cycles Waste Manage 23(1):205–213 Google Scholar

- El Asri O (2023) Anaerobic biodegradation: the anaerobic digestion process. Handbook of Biodegradable Materials, pp. 85–110.

- Bajpai P (2017) Basics of anaerobic digestion process. Anaerobic Technology in Pulp and Paper Industry, pp. 7–12.

- Adekunle KF, Okolie JA (2015) A review of biochemical process of anaerobic digestion. Adv Biosci Biotechnol 06(03):205–212 Google Scholar

- Hatti-Kaul R, Mattiasson B (2016) Anaerobes in industrial- and environmental biotechnology. Advances in Biochemical Engineering/Biotechnology, pp. 1–33.

- Slezak R, Krzystek L, Ledakowicz S (2015) Degradation of municipal solid waste in simulated landfill bioreactors under aerobic conditions. Waste Manage 43:293–299 CASGoogle Scholar

- Fredi G, Dorigato A (2021) Recycling of bioplastic waste: a review. Adv Ind Eng Polym Res 4(3):159–177 CASGoogle Scholar

- Cosquer R, Pruvost S, Gouanvé F (2021) Improvement of barrier properties of biodegradable polybutylene succinate/graphene nanoplatelets nanocomposites prepared by melt process. Membranes 11(2):151 CASPubMedPubMed CentralGoogle Scholar

- Lule Z, Kim J (2020) Thermally conductive polybutylene succinate composite filled with Si-O-N-C functionalized silicon carbide fabricated via low-speed melt extrusion. Eur Polymer J 134:109849 CASGoogle Scholar

- Lule Z, Kim J (2021) Compatibilization effect of silanized SiC particles on polybutylene adipate terephthalate/polycarbonate blends. Mater Chem Phys 258:123879 CASGoogle Scholar

- Lee Y, Wu T (2021) Synthesis and physical properties of biodegradable nanocomposites fabricated using acrylic acid-grafted poly(butylene carbonate-co- terephthalate) and organically-modified layered zinc phenylphosphonate. J Polym Environ 30(3):896–906 Google Scholar

- Meng Q, Pepper K, Cheng R, Howdle S, Liu B (2016) Effect of supercritical CO2on the copolymerization behavior of cyclohexene oxide/CO2and copolymer properties with DMC/Salen-Co(III) catalyst system. J Polym Sci, Part A: Polym Chem 54(17):2785–2793 ADSCASGoogle Scholar

- Ogunsona E, Misra M, Mohanty A (2016) Sustainable biocomposites from biobased polyamide 6,10 and biocarbon from pyrolyzed miscanthus fibers. J Appl Polym Sci, 134(4).

- Muthuraj R, Mekonnen T (2018) Recent progress in carbon dioxide (CO2) as feedstock for sustainable materials development: co-polymers and polymer blends. Polymer 145:348–373 CASGoogle Scholar

- Dong T, Yun X, Shi C, Sun W, Fan G, Jin Y (2014) Improved mechanical and barrier properties of PPC multilayer film through interlayer hydrogen bonding interaction. Polym Sci, Ser A 56(6):830–836 CASGoogle Scholar

- Li X, Meng L, Zhang Y, Qin Z, Meng L, Li C, Liu M (2022) Research and application of polypropylene carbonate composite materials: a review. Polymers 14(11):2159 CASPubMedPubMed CentralGoogle Scholar

- Liu J, Li R, Yang B (2020) Carbon dots: a new type of carbon-based nanomaterial with wide applications. ACS Cent Sci 6(12):2179–2195 CASPubMedPubMed CentralGoogle Scholar

- Panchal S, Vasava D (2020) Biodegradable polymeric materials: synthetic approach. ACS Omega 5(9):4370–4379 CASPubMedPubMed CentralGoogle Scholar

- Abd El-Magied M, Galhoum A, Atia A, Tolba A, Maize M, Vincent T, Guibal E (2017) Cellulose and chitosan derivatives for enhanced sorption of erbium(III). Colloids Surf, A 529:580–593 CASGoogle Scholar

- Ardean C, Davidescu C, Nemeş N, Negrea A, Ciopec M, Duteanu N, Negrea P, Duda-Seiman D, Musta V (2021) Factors influencing the antibacterial activity of chitosan and chitosan modified by functionalization. Int J Mol Sci 22(14):7449 CASPubMedPubMed CentralGoogle Scholar

- Guo B, Ma P (2014) Synthetic biodegradable functional polymers for tissue engineering: a brief review. Sci China Chem 57(4):490–500 CASGoogle Scholar

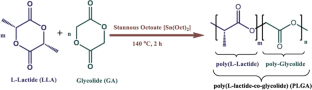

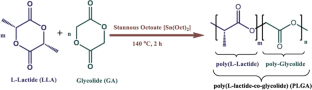

- Hu Y, Daoud W, Cheuk K, Lin C (2016) Newly developed techniques on polycondensation, ring-opening polymerization and polymer modification: focus on poly (lactic acid). Materials 9(3):133 ADSPubMedPubMed CentralGoogle Scholar

- Adhami W, Bakkour Y, Rolando C (2021) Polylactones synthesis by enzymatic ring opening polymerization in flow. Polymer 230:124040 CASGoogle Scholar

- Butreddy A, Gaddam R, Kommineni N, Dudhipala N, Voshavar C (2021) PLGA/PLA-based long-acting injectable depot microspheres in clinical use: production and characterization overview for protein/peptide delivery. Int J Mol Sci 22(16):8884 CASPubMedPubMed CentralGoogle Scholar

- Arrieta M, López J, Rayón E, Jiménez A (2014) Disintegrability under composting conditions of plasticized PLA–PHB blends. Polym Degrad Stab 108:307–318 CASGoogle Scholar

- Razak N, Mohamed R (2021) Antimicrobial sustainable biopolymers for biomedical plastics applications – an overview. Polimery 66(11–12):574–583 CASGoogle Scholar

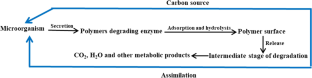

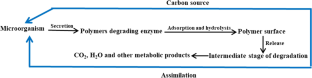

- Lim B, Thian E (2022) Biodegradation of polymers in managing plastic waste — a review. Sci Total Environ 813:151880 ADSCASPubMedGoogle Scholar

- Muhammadi S, Afzal M, Hameed S (2015) Bacterial polyhydroxyalkanoates- eco-friendly next generation plastic: production, biocompatibility, biodegradation, physical properties and applications. Green Chem Lett Rev 8(3–4):56–77 Google Scholar

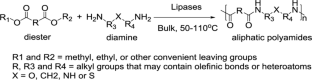

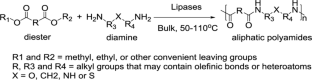

- Jiang Y, Loos K (2016) Enzymatic synthesis of biobased polyesters and polyamides. Polymers 8(7):243 PubMedPubMed CentralGoogle Scholar

- Pellis A, Comerford J, Weinberger S, Guebitz G, Clark J, Farmer T (2019) Enzymatic synthesis of lignin derivable pyridine-based polyesters for the substitution of petroleum derived plastics. Nat Commun 10(1):1762 ADSPubMedPubMed CentralGoogle Scholar

- Gu Q, Maslanka W, Cheng H (2008) Enzyme-catalyzed polyamides and their derivatives. ACS Symposium Series, pp.309–319.

- Chao Q, Ding Y, Chen Z, Xiang M, Wang N, Gao X (2020) Recent progress in chemo-enzymatic methods for the synthesis of N-glycans. Front Chem 8:513 ADSCASPubMedPubMed CentralGoogle Scholar

- Cai X, Wang N, Lin X (2006) The preparation of polymerizable, optically active non-steroidal anti-inflammatory drugs derivatives by irreversible enzymatic methods. J Mol Catal B Enzym 40(1–2):51–57 CASGoogle Scholar

- Knani D, Gutman A, Kohn D (1993) Enzymatic polyesterification in organic media. Enzyme-catalyzed synthesis of linear polyesters. I. Condensation polymerization of linear hydroxyesters. II. Ring-opening polymerization of ε-caprolactone. J Polym Sci Part A: Polym Chem 31(5):1221–1232 ADSCASGoogle Scholar

- Narancic T, Cerrone F, Beagan N, O’Connor K (2020) Recent advances in bioplastics: application and biodegradation. Polymers 12(4):920 CASPubMedPubMed CentralGoogle Scholar

- ASTM D 6400-99, 1976. Standard specification for compostable plastics, annual book of standards. ASTM, Philadelphia

- Gu J (2003) Microbiological deterioration and degradation of synthetic polymeric materials: recent research advances. Int Biodeterior Biodegradation 52(2):69–91 CASGoogle Scholar

- Billingham N (2001) Handbook of polymer degradation. Polym Degrad Stab 74(3):585 Google Scholar

- Luckachan G, Pillai C (2011) Biodegradable polymers- a review on recent trends and emerging perspectives. J Polym Environ 19(3):637–676 CASGoogle Scholar

- Behera S et al (2022) Polyhydroxyalkanoates, the bioplastics of microbial origin: properties, biochemical synthesis, and their applications. Chemosphere 294:133723 CASPubMedGoogle Scholar

- Sehgal R, Gupta R (2020) Polyhydroxyalkanoate and its efficient production: an eco-friendly approach towards development. 3Biotech 10(12):549 Google Scholar

- Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv 3(7):e1700782 ADSPubMedPubMed CentralGoogle Scholar

- Haque MJ, Rahman MS (2023) Biodegradation of industrial materials. Handbook of Biodegradable Materials, pp. 1407–1448.

- Mohanan N, Montazer Z, Sharma P, Levin D (2020) Microbial and enzymatic degradation of synthetic plastics. Front Microbiol 11:580709 PubMedPubMed CentralGoogle Scholar

- Kumar Tiwari A, Gautam M, Maurya H (2018) Recent development of biodegradation techniques of polymer. Int J Res 6(6):414–452 Google Scholar

- Liu L, Xu M, Ye Y, Zhang B (2022) On the degradation of (micro)plastics: degradation methods, influencing factors, environmental impacts. Sci Total Environ 806:151312 ADSCASPubMedGoogle Scholar

- Filiciotto L, Rothenberg G (2020) Biodegradable plastics: standards, policies, and impacts. Chemsuschem 14(1):56–72 PubMedPubMed CentralGoogle Scholar

- Pepelnjak T et al (2023) Influence of process parameters on the characteristics of additively manufactured parts made from advanced biopolymers. Polymers 15(3):716 CASPubMedPubMed CentralGoogle Scholar

- Flórez M, Cazón P, Vázquez M (2023) Selected biopolymers’ processing and their applications: a review. Polymers 15(3):641 PubMedPubMed CentralGoogle Scholar

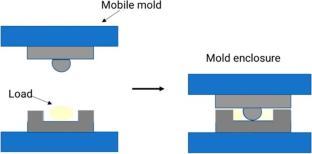

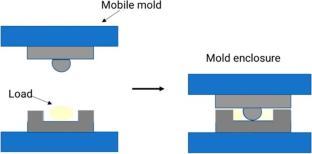

- Tatara RA (2017) Compression molding. Applied Plastics Engineering Handbook, pp. 291–320.

- Udayakumar GP et al (2021) Ecofriendly biopolymers and composites: preparation and their applications in water-treatment. Biotechnol Adv 52:107815 CASPubMedGoogle Scholar

- Scaffaro R, Citarrella MC, Gulino EF (2022) Opuntia Ficus indica based green composites for NPK fertilizer controlled release produced by compression molding and fused deposition modeling. Compos A Appl Sci Manuf 159:107030 CASGoogle Scholar

- Valencia-Sullca C et al (2018) Physical and antimicrobial properties of compression-molded cassava starch-chitosan films for meat preservation. Food Bioprocess Technol 11(7):1339–1349 CASGoogle Scholar

- Mallick PK (2017) Compression molding. Processing of Polymer Matrix Composites, pp. 171–200.

- Bealer EJ et al (2020) Protein–polysaccharide composite materials: fabrication and applications. Polymers 12(2):464 CASPubMedPubMed CentralGoogle Scholar

- Guerrero P et al (2019) Crosslinking of chitosan films processed by compression molding. Carbohyd Polym 206:820–826 CASGoogle Scholar

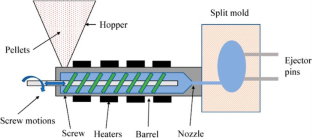

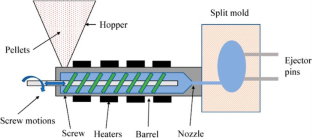

- Marçal RLSB (2016) Biomaterials produced by injection molding. Reference Module in Materials Science and Materials Engineering [Preprint].

- Do Val Siqueira L et al (2021) Starch-based biodegradable plastics: methods of production, challenges and future perspectives. Curr Opin Food Sci 38:122–130 CASGoogle Scholar

- Félix M et al (2015) Development of crayfish protein-PCL biocomposite material processed by injection moulding. Compos B Eng 78:291–297 Google Scholar

- Relinque J et al (2019) Development of surface-coated polylactic acid/polyhydroxyalkanoate (PLA/PHA) nanocomposites. Polymers 11(3):400 PubMedPubMed CentralGoogle Scholar

- Liu W et al (2020) Preparation, reinforcement and properties of thermoplastic starch film by Film Blowing. Food Hydrocoll 108:106006 CASGoogle Scholar

- McKeen LW (2017) Production of films, containers, and membranes. Permeability Properties of Plastics and Elastomers, pp. 41–60

- Mendes JF et al (2016) Biodegradable polymer blends based on corn starch and thermoplastic chitosan processed by extrusion. Carbohyd Polym 137:452–458 CASGoogle Scholar

- Scaffaro R et al (2022) Green composites based on biodegradable polymers and Anchovy (engraulis encrasicolus) waste suitable for 3D printing applications. Compos Sci Technol 230:109768 CASGoogle Scholar

- Ahn J-H et al (2021) 3D-printed biodegradable composite scaffolds with significantly enhanced mechanical properties via the combination of binder jetting and capillary rise infiltration process. Addit Manuf 41:101988 CASGoogle Scholar

- Farazin A et al (2023) 3D bio-printing for use as bone replacement tissues: a review of Biomedical Application. Biomed Eng Adv 5:100075 Google Scholar

- Olegovich Osidak E et al (2020) Collagen as bioink for bioprinting: a comprehensive review. Int J Bioprinting 6(3)

- Rojas-Martínez LE et al (2020) 3D printing of PLA composites scaffolds reinforced with keratin and chitosan: effect of geometry and structure. Eur Polymer J 141:110088 Google Scholar

- Li N et al (2021) 3D printing to innovate biopolymer materials for demanding applications: a review. Mater Today Chem 20:100459 CASGoogle Scholar

- Kjeldsen A, Price M, Lilley C, Guzniczak E, Archer I (2018) A review of standards for biodegradable plastics. Ind Biotechnol Innov Cent 33(1)

- Karamanlioglu M, Preziosi R, Robson GD (2017) Abiotic and biotic environmental degradation of the bioplastic polymer poly (lactic acid): a review. Polym Degrad Stab 137:122–130 CASGoogle Scholar

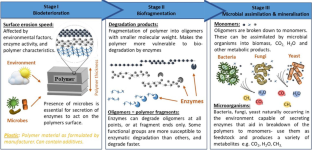

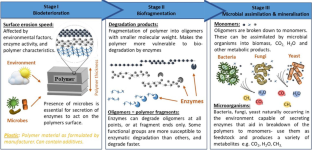

- Joseph E et al. (2022) Fundamentals of polymer biodegradation mechanisms. Biodegradable Polymers in the Circular Plastics Economy pp. 17–58

- Rostamzad H (2022) Active and intelligent biodegradable films and polymers. Biodegradable Polymers, Blends and Composites pp. 415–430

- Salazar SA, Abdulhameed S, Sánchez M del (2023) Biodegradation of polymers. Biodegradable Polymers pp. 1–12

- Zeenat et al (2021) Plastics degradation by microbes: a sustainable approach. J King Saud Univ - Sci 33(6):101538 Google Scholar

- Sharma R et al (2020) Microbial fermentation and its role in quality improvement of fermented foods. Fermentation 6(4):106 CASGoogle Scholar

- El Menofy NG, Khattab AM (2023) Plastics biodegradation and Biofragmentation. Handb Biodegradable Mater pp. 571–600

- Folino A et al (2020) Biodegradation of wasted bioplastics in natural and industrial environments: a review. Sustainability 12(15):6030 CASGoogle Scholar

- Glaser J (2019) Biological degradation of polymers in the environment. Plast Environ.

- Gewert B, Plassmann MM, MacLeod M (2015) Pathways for degradation of plastic polymers floating in the marine environment. Environ Sci Process Impacts 17(9):1513–1521 CASPubMedGoogle Scholar

- Dimassi SN et al (2022) Degradation-fragmentation of marine plastic waste and their environmental implications: a critical review. Arab J Chem 15(11):104262 CASGoogle Scholar

- Strafella P et al (2022) Distribution of microplastics in the marine environment. Handb Microplastics Environ pp. 813–847

- Yousif E, Haddad R (2013) Photodegradation and photostabilization of polymers, especially polystyrene: review. SpringerPlus 2(1):1–32 CASGoogle Scholar

- Keiluweit M et al (2017) Anaerobic microsites have an unaccounted role in soil carbon stabilization. Nat Commun 8(1):1771 ADSPubMedPubMed CentralGoogle Scholar

- Groeneveld I et al (2023) Parameters that affect the photodegradation of dyes and pigments in solution and on substrate – an overview. Dyes Pigm 210:110999 CASGoogle Scholar

- Rashid MI et al (2016) Bacteria and fungi can contribute to nutrients bioavailability and aggregate formation in degraded soils. Microbiol Res 183:26–41 CASPubMedGoogle Scholar

- Rosenboom J-G, Langer R, Traverso G (2022) Bioplastics for a circular economy. Nat Rev Mater 7(2):117–137 ADSPubMedPubMed CentralGoogle Scholar

- Ahsan WA et al (2023) Biodegradation of different types of bioplastics through composting—a recent trend in Green Recycling. Catalysts 13(2):294 CASGoogle Scholar

- Law KL, Narayan R (2021) Reducing environmental plastic pollution by designing polymer materials for managed end-of-life. Nat Rev Mater 7(2):104–116 ADSGoogle Scholar

- Scaffaro R et al (2019) Degradation and recycling of films based on biodegradable polymers: a short review. Polymers 11(4):651 CASPubMedPubMed CentralGoogle Scholar

- Singh B, Sharma N (2008) Mechanistic implications of plastic degradation”. Polym Degrad Stab 93(3):561–584 CASGoogle Scholar

- Ramasubramanian G, Madbouly S (2015) Thermal and oxidative degradation behavior of polymers and nanocomposites. Reactions and Mechanisms in Thermal Analysis of Advanced Materials, pp. 127–164.

- Fukushima K, Feijoo JL, Yang M-C (2013) Comparison of abiotic and biotic degradation of PDLLA, PCL and partially miscible PDLLA/PCL Blend. Eur Polymer J 49(3):706–717 CASGoogle Scholar

- Tsutsumi C et al (2003) The enzymatic degradation of commercial biodegradable polymers by some lipases and chemical degradation of them. Macromol Symp 197(1):431–442 CASGoogle Scholar

- Mofokeng JP, Luyt AS (2015) Morphology and thermal degradation studies of melt-mixed poly (lactic acid) (pla)/poly(ε-caprolactone) (PCL) biodegradable polymer blend nanocomposites with TIO2 as filler. Polym Testing 45:93–100 CASGoogle Scholar

- Müller C, Townsend K, Matschullat J (2012) Experimental degradation of polymer shopping bags (standard and degradable plastic, and biodegradable) in the gastrointestinal fluids of sea turtles. Sci Total Environ 416:464–467 ADSPubMedGoogle Scholar

- Yin G-Z, Yang X-M (2020) Biodegradable polymers: a cure for the planet, but a long way to go. J Polym Res 27(2):32 Google Scholar

- Gomaa M (2022) Biodegradable plastics based on algal polymers: recent advances and applications. Handb Biodegradable Mater pp. 1–31

- Samir A et al (2022) Recent advances in biodegradable polymers for sustainable applications. Mater Degrad 6(1):68 CASGoogle Scholar

Author information

Authors and Affiliations

- Department of Chemical Engineering, Hacettepe University, Beytepe, Ankara, 06800, Turkey Oznur Kaya Cakmak

- Oznur Kaya Cakmak

You can also search for this author in PubMed Google Scholar

Contributions

The author confirms sole responsibility for the following: study conception, design, and manuscript preparation.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Consent for Publication

Competing Interests

The author declares no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cakmak, O.K. Biodegradable Polymers—a Review on Properties, Processing, and Degradation Mechanism. Circ.Econ.Sust. 4, 339–362 (2024). https://doi.org/10.1007/s43615-023-00277-y

- Received : 16 January 2023

- Accepted : 27 May 2023

- Published : 11 July 2023

- Issue Date : March 2024

- DOI : https://doi.org/10.1007/s43615-023-00277-y

Share this article

Anyone you share the following link with will be able to read this content:

Get shareable link

Sorry, a shareable link is not currently available for this article.

Copy to clipboard

Provided by the Springer Nature SharedIt content-sharing initiative

Keywords

- Biodegradable polymers

- Biobased plastics

- Synthesis methods

- Biodegradation mechanism

- Application areas